Solid WPC Door Frame Making Machine

2024-11-30

HSJZ-65/132(37kw) 150~180kg/hr

Product Description

HSJZ-65/132 Solid WPC Door Frame Making Machine

This is WPC Profile Making Machine, which is specially designed for WPC Door Frame manufacturing. The whole plant will consist of HSJZ-65/132 Conical Twin Screw Extruder, 9m Vacuum Cooling Platform, Traction Machine, Cutting Machine, Stacker.

This Extruder is designed specially for processing Higher-Percent-Calcium Mixed PVC Material, to manufacture WPC Foamed Door Frame. The Extruder installs with 37kw driving motor , which will produce 150-200kg/hr. Our SCREW & BARREL Sets is specially designed for 200-260% Calcium mixed. It has the advantages of high tenacity, high impact, good bending performance, high temperature resistance, etc.

MAIN COMPONENTS of full plant

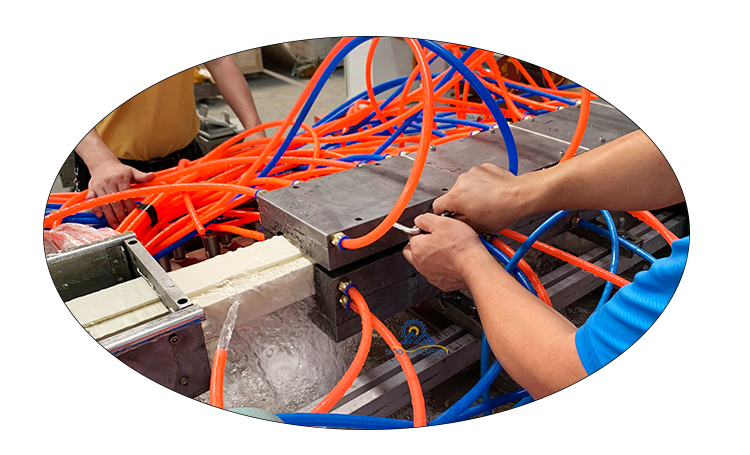

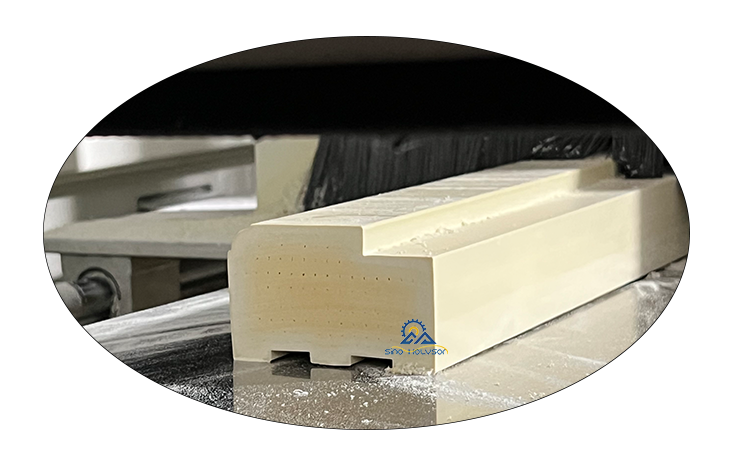

WPC Door Frame Mould

The Full-Set mould includes with Hot-extrusion Die Head, and Vacuum Cooling Shaping Mould and 6m-long bathing water tank.

We have differend mould dimension at your choice, “customized service” available also.

Vacuum Cooling Platform

Vacuum Cooling Platform is length-9000mm designed. Working with chilled water will quickly shape and cool down the frame.

Installed with turbo vacuum pump to guarantee the frame well-shaped.

The Cooling Platform can be adjusted back-forward, right-left and up-down.3

-Dimension Adjustment system make the cooling platform more flexibility, and let the production more convenient.

Automatic Traction & Cutting Machine

This is an Automatic Traction machine, which is double caterpillar design.

The driving system used AC motor1.5kw, working with hard-teeth gear reducer, which is effective, accurate and reliable.

The Cutting machine adopts blades cutter, with PLC-smart-panel to realize automatic cutting.

Cooperated with an Omron Encoder, it will cut the frame at your set length.

It automatically mark the quantity of the cutting pieces. Auto-Alarm system will work if any fault happens.

Automatic Pneumatic Stacker Unit

The Stacker machine is pneumatically controlled by two cylinders.

It will be able to discharge the frames after cutting automatically,

which greatly reduce the labor cost.

It is safe and reliable designed, operation is easy and convenient.

WPC Door Frame Making Machine

Solid Foamed Door Frame Making Machine

Spare Used Part Needed