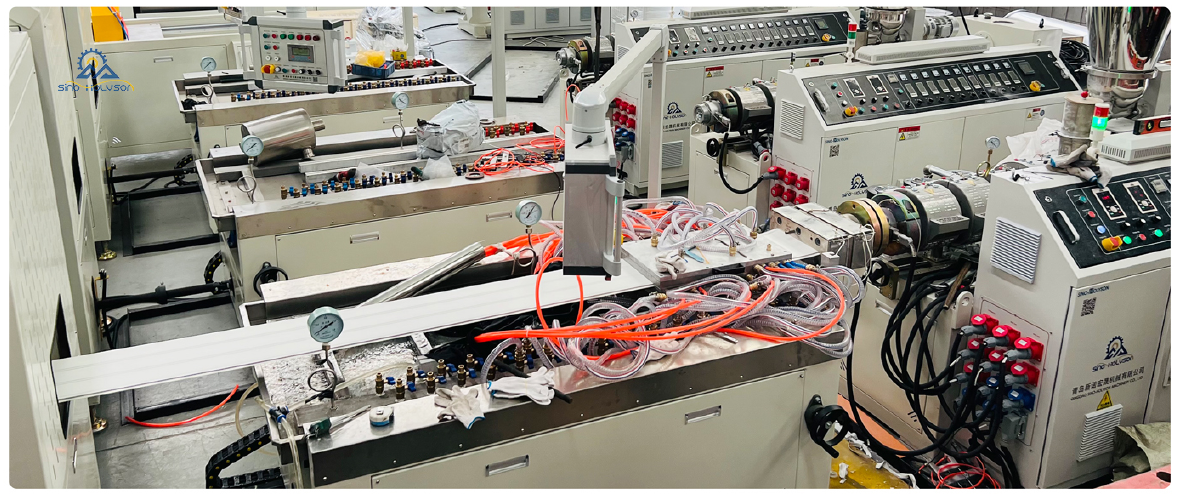

PVC Flute Wall Panel making machine

2024-07-06

7/ 9-Grooved Mould

Product Description

HSJZ-65/132 Flute PVC Wall Panel Making Machine

Width: 250mm / 300mm 7/9 - Grooved

PVC Flute Wall Panel Making Machine is used for manufacturing PVC (polyvinyl chloride) flute wall panels. These panels are commonly used in construction and interior design for applications such as ceilings, partitions, and wall cladding. The machine typically consists of several components and processes that work together to produce the PVC flute wall panels.

Here is a general overview of the process:

Material Preparation: PVC resin, additives, and other ingredients are mixed together to create a PVC compound. The compound is then melted and extruded into a specific shape, usually in the form of a sheet or panel.

Flute Formation: The extruded PVC sheet is passed through a flute forming section of the machine. Flutes are the hollow, rib-like structures that provide strength and rigidity to the panel. The machine uses specialized tools or molds to create the desired flute pattern on the surface of the sheet.

Cooling and Sizing: After the flute formation, the PVC sheet is cooled using a cooling system to solidify the material and stabilize its shape. Sizing tools or cutting devices are used to trim the sheet to the desired width and length.

Surface Treatment: The flute wall panels may undergo additional surface treatments based on design requirements. This can include processes such as embossing, printing, or laminating to enhance the appearance or functionality of the panels.

Stacking and Packaging: Once the PVC flute wall panels are produced, they are stacked and packaged for shipping and distribution. This may involve automated stacking systems and packaging equipment to ensure the panels are protected during transportation.

It's important to note that the specific design and features of a PVC flute wall panel machine can vary depending on the manufacturer and the desired end product. Additionally, advancements in technology and machinery may have occurred beyond my knowledge cutoff in September 2021. Therefore, it's advisable to consult with a manufacturer or supplier specializing in such machinery for the most up-to-date information on PVC flute wall panel machines.

Main Machine List:

- HSJZ-65/132 Conical Twin Screw Extruder(37kw)

- Vacuum Cooling Platform

- Double Claw Traction Machine

- Inline film Laminating machine

- Automatic Cutting Machine

TECHNICAL DATA

Driving Motor: 18.5kw

Production Capacity: 45-65kg/h

Application: Pipe Manufacturing.

Exacted from Corrugated Conduit Pipe Machine

PVC flute panel machine

pvc panel machine

pvc panel making machine

Spare Used Part Needed