HSJZ-80/156 PVC Aritificial Marble Sheet Making Machine

2024-09-02

HSJZ-80/156 & HSJZ-92/188 Model

Product Description

HSJZ-80/156 PVC Artificial Marble Sheet Making Machine

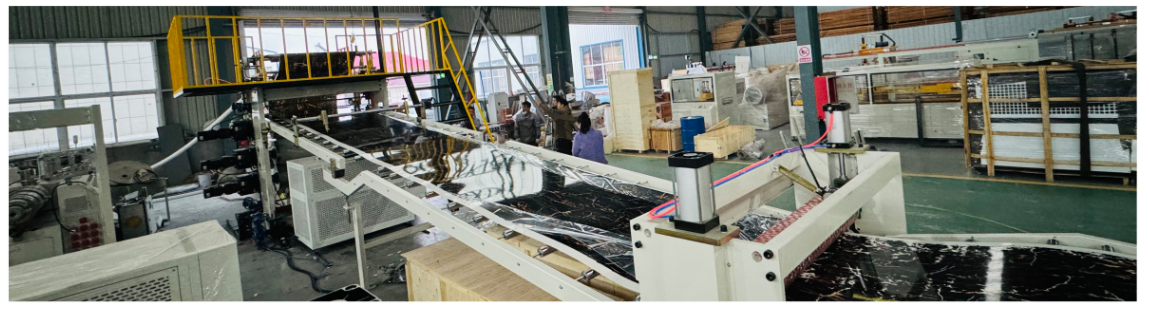

PVC Artificial Marble Sheet Making Machine is designed to produce synthetic marble sheet, which also known as artificial marble sheet, UV marble sheet. The machine also is called PVC Imitation Marble Sheet Machine, UV Marble Sheet machine. The PVC marble sheet could be able to instead of real marble tiles, for countertop, wall and floor application. It is used for wall decoration, like hotel wall, restaurant hall, entertainment wall. It will greatly reducing the cost using PVC marble sheet.

MAIN COMPONENTS of full plant:

NO. | Item | Quantity |

1. | HSJZ-80/156 Conical Twin Screw Extruder(75kw) | 1 set |

2. | T-Die(Width -1350mm) | 1 set |

3. | 3-Roll Calendar Machine | 1 set |

3.1 | Inline - Film Laminating Unit / Inline - Film Hot-Stamping Unit | 1 set |

3.2 | 3-in-1 Temperature Controller Unit | 1 set |

4. | Cooling Platform(with margin trimming) | 1 set |

5. | Double Rubber Roller Traction Machine | 1 set |

6. | Automatic Pneumatic Cutting Machine | 1 set |

7. | Panel Discharger | 1 set |

| 8. | Automatic Palletizer Unit(this is optional choice) | 1 set |

HSJZ-80/156 Conical Twin Screw Extruder

This Extruder is designed specially for processing Higher-Percent-Calcium Mixed PVC Material, to manufacture PVC Artificial Marble Sheet. The Extruder installs with 75kw driving motor , which will produce 350-500kg/hr. Our SCREW & BARREL Sets is specially designed for 200-300% Calcium mixed. It has the advantages of high tenacity, high impact, good bending performance, high temperature resistance, etc.

T-Die Width: 1350mm

The material is then forced through the lips of the die with a short, flat approach. An accurate uniform shape of the PVC Marble Sheet is achieved from the T-die. The lips of the die determine the thickness of the PVC marble sheet produced. This implies that you may adjust the thickness of the sheet as desired.

PVC marble sheet die head is 1350mm width, to produce 1220mm width and 2-5mm thickness samples.

PVC marble sheet machine has a continuous production process. We can make the length of the marble sheet that we want; typically, the finished marble sheet is 1220 × 2440mm in size.

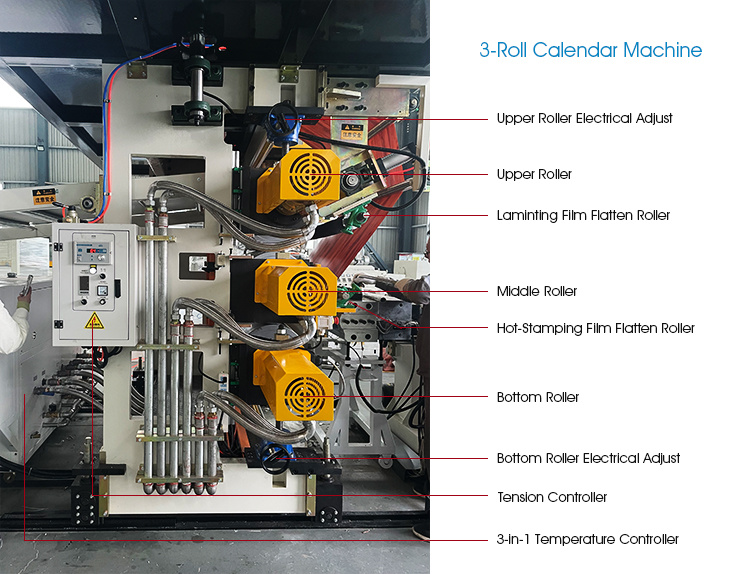

3-Roll Calendar Machine

Three-roller calendar machine is the most key important unit from this production line. A heavy duty and super processed roller is a best guarantee for smoothy and glossy sheet. The three-roller calendar rollers are seperately controlled, with individual driving motor and reducer set.

This Roller System ensures the PVC marble sheet is perfectly level before applying any exterior finishing to its surface. It has an online lamination device and hot-stamping device for applying either PVC lamination film or PVC hot-stamping film. The pattern of the film can be chosen and designed as per market preference.

Cooling Platform + Haul-off Machine (with margin trimming)

The Cooling Platform is 6 meters long, for cooling down the marble sheet grandually. By each side of the cooling platform, it installed with blade margin trimmer. The trimming blade will automatically cut the sheet edge clean and neatly. The Haul-off Machine is made by two rubber wheel, which is pneumatically clamping and loosen, which is very easy and conveniently operation. Two-Rubber Traction/Haul-off machine is driven by 2.2kw AC motor. Rubber Roller size is φ240×1450mm. Roller open-close by hydraulic cylinder pneumatically.

Automatic Pneumatic Cutting Machine

The cutting machine will cut the sheet at the length as pre-set, with Omron brand encoder unit. Hydraulic cutting is very neat and clean, non-dust.

Automatic Panel Pallatizer Machine(Discharger)

Automatic Palletizer will discharge the the sheets, without using any human labor, which greatly reduce manufacture cost. The machine is installed with a smart Siemens Panel for easy operation. This machine is an optional choice with the extrusion machine.

UV Marble Sheet Making Machine

Artificial marble sheet machine

PVC Marble Sheet Machine

Spare Used Part Needed