Hollow WPC Window Door Frame Making Machine

2024-09-23

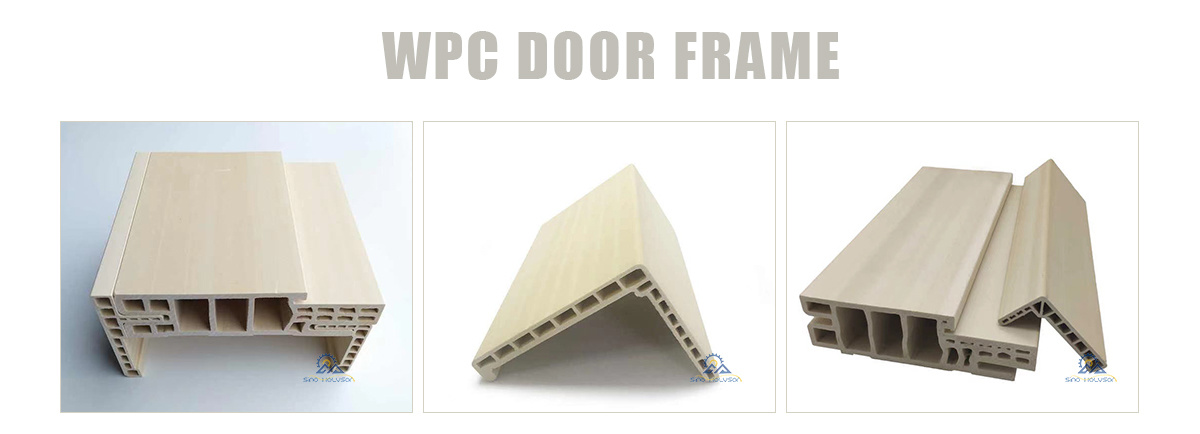

Product Description

HSJZ-65/132 WPC Door Frame Profile Making Machine

This WPC Profile making machine is specially designed for WPC Hollowed Door Framework manufacturing. The whole plant will include a HSJZ-65/132 Conical Twin Screw Extruder, installed with 37kw driving motor, the output ranges from 100-200kg/hr. The Screw & Barrel set is Demaj brand, which is a top brand for wpc material processing. Ater the extruder unit, it followed with a 6m Vacuum Cooling Platform, Double-Caterpillar Traction machine, Automatic Cutting machine and Panel Stacker. In this way, it composed into a full production plant. (PLC Smart Panel is an optional choice.)

MAIN COMPONENTS of full plant

| NO. | Item | Quantity |

| 1. | HSJZ-65/132 Conical Twin Screw Extruder | 1 set |

| 1.2 | Automatic Screw Hopper Loader | 1 set |

| 2. | WPC Door Frame Mould | 1 set |

| 3. | Vacuum Coolling Platform | 1 set |

| 4. | Automatic Traction Machine | 1 set |

| 5. | Blade Cutting Machine(with Dust Collector) | 1 set |

| 6. | Panel Stacker | 1 set |

| 7. | HSRL-Z 300/600L PVC Mixer | 1 set |

| 8. | Hot Stamping / Laminating Machine / Hot Glue Laminating Machine(Optional) | 1 set |

Spare Used Part Needed