HSJZ-53/128 PVC Wall Panel Making Machine(Pro-Design)

2024-07-22

Capacity: 15000ft/day

Product Description

HSJZ-53/128 PVC Wall Panel Making Machine

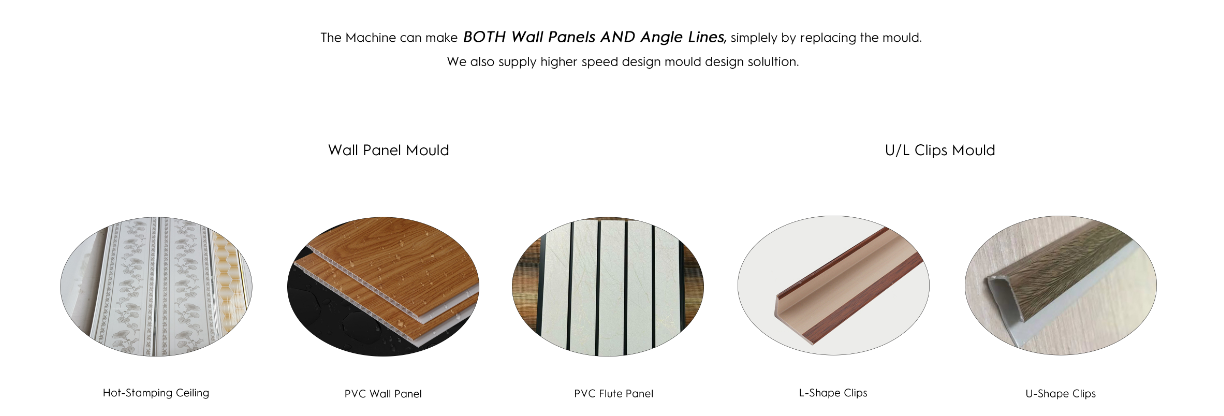

This PVC Wall Panel Making Machine is with our latest design, it guarantees a more stable and reliable performance, comparing with most market machines. We supply Standard Design and Professional Design choice, to meet different customer requirement. The machine can also be able to manufacture both PVC wall/ceiling panels, and PVC U/L Angle Lines.

HSJZ-53/128 PVC Wall Panel Making Machine is used to produce PVC Wall Panels, PVC Ceiling Panels, and PVC Flute Wall Panels. PVC(Polyvinyl chloride) wall panels are commonly used in interior wall cladding and paneling. The machine is designed to automate the production process of PVC wall panels, allowing for efficient and consistent manufacturing. PVC wall panel machines come in various sizes and configurations depending on the production capacity and specific requirements of the manufacturer. They can range from small-scale manual machines to fully automated production lines capable of high-volume manufacturing.

The Main Machine List of full plant:

| NO. | Item | Quantity | ||

| 1. | HSJZ-53/128 Conical Twin Screw Extruder | 1 set | ||

| 2. | Vacuum Coolling Platform | 1 set | ||

| 3. | Two Caterpillar Traction Machine | 1 set | ||

| 4. | Inline Fillm Hot-Stamping and Laminating Machine | 1 set | ||

| 5. | Automatic Blade Cutting Machine | 1 set | ||

| 6. | Automatic Panel Stacker Unit | 1 set | ||

| 7. | Wall Panel Mould(Specially Customized) |

|

Detailed Introduction for the machine:

*** HSJZ-53/128 Conical Twin Screw Extruder

This twin screw extruder model HSJZ-53/128, installed with 22kw driving motor, extrusion output at 100-180kg/hr, it can make 15000ft daily. This is the most popular design machine in the market. The extruder is able to take 200-260% shares of calcium carbonate into production, which greatly reduce the production cost. There will be a complimentary auto-loader with the extruder for the whole production line.

**** Vacuum Cooling Platform(Length 1500mm)

Cooling and Sizing: Once the PVC material is extruded, it goes through a cooling process to solidify and stabilize the panels. Cooling can be achieved through water baths or air cooling systems. Sizing units are used to trim the panels to the desired length and width.

**** Two Caterpillar Traction Machine

**** Inline Hot-Stamping and Laminating Machine

Embossing and Lamination (Optional): Some machines may include additional processes like embossing or laminating the surface of the PVC panels to enhance their appearance and texture. Embossing can create patterns or textures on the panels, while lamination can add a protective layer or decorative finish.

**** Automatic Cutting Machine

The movement of cutting platform is controlled by cylinder, ensure that the longituinal speed is snychronized with the production line speed. Cutting and Stacking: After the panels are fully processed, they are cut into individual pieces of the desired length. The cut panels are then stacked or packed for storage or transportation.

Features and Application:

1. The equipment adapts to various formulations, the ratio of calcium can be increased up to 50%- -250%,while the required accessories can be reduced by 30%.

2. The ceiling the extruder products has an exquisite appearance and uniform plasticization.

3. Laser tracking eliminates problems regarding the extrusion flow rate, whichelps achieve automation of the entire extrusion process.

4. The PVC ceiling extrusion machine has auto-alarm functions in case of emergency, through the use of PID controller. Which is mainly used in the area of pvc ceiling, integrated ceiling, luggage board, ceiling corner etc.

PVC Wall Panel Making Machine

PVC Ceiling Panel Making Machine

PVC Flute Panel Machine

Spare Used Part Needed